Heritage & Service

We are proud to announce that Scindia Kanya Vidyalaya is the Overall Winner of the 6th Shrimant Madhavrao Scindia Dharohar Fest 2022: Kerala Heritage. Being the host school, the Trophy went to the runners-up team: Rajmata Krishna Kumari Girls School. Accolades to the winning teams for creating the very pure essence of God’s Own Country: Kerala.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

All the creativity the participants rendered in this Dharohar was displayed in the Madhav Bhawan courtyard for everyone to admire. We had exhibits from- E-Greeting, Cartooning, Mulapayachitrarachna, Acrylic on Canvas, Chitrattayyalpani, Kollam and Shilpvela.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The participants performed various folk dances from different regions of Kerala and uplifted the mood for the concluding day of the 6th Dharohar.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The students presented the Kalaripayattu (traditional martial art form) with grace and prowess, mentored by the very talented Mr. Jothis Menon.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The students rendered Mulapayachitrarachna (Bamboo Mat Painting), a distinctive art form of Kerala, with the theme “Kerala Boat Race ''. This art form is rarely practiced nowadays but was revived in the event.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The students showcased the final presentation of the auspicious elephant on the last day of Shilpvela. Kudos to their immense talent and hardwork!

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The participants sang melodious folk songs which spoke of different stories of the life of the people from the heart of Kerala.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

A “Cartooning” event was hosted in tribute to popular Malayali cartoons which was a fun addition to the fest.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

SKV hosted a cooking competition or “Pachakam”. Through authentic Kerala cuisine, the participants showed their culinary skills.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Sahityam- One person Dramatics, based on “Randamoozham”, a novel by M. T. Vasudevan Nair set the stage for the 2nd day of Dharohar.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Sahityam- One person Dramatics, based on “Randamoozham”, a novel by M. T. Vasudevan Nair set the stage for the 2nd day of Dharohar.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The Dharohar event “Chitrattayyalpani” was all about intricate embroidery being sewn by the participants.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Dharohar has officially commenced with the first event “Acrylic On Canvas” where participants were instructed to paint the Kerala Landscape.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

The day one of “Shilpvela-Sculpture” was about participants creating a clay representation of the religious elephant in Kerala’s ritualistic procession.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Dharohar will be incomplete without Kollam- the traditional rangoli art of Kerala. The participants presented their artistic talent for everyone to see.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

SASHA-The humanoid robot created by the SKVians is the crowning glory of SKV. Sasha is the perfect blend of ultra-modern robotics draped in the festivities of Dharohar. Created by the genius students, we are proud to take our school to new heights.

This Dharohar is blessed with the Thiruvadhira dance by our students and the glorious Theyyam (religious dance) during the inaugural ceremony.

Dr. Suresh K Goel, our Chief Guest released the official brochure for 6th Shrimant Madhavrao Scindia Dharohar Fest: Kerala Heritage.

The inauguration ceremony started with auspicious Sringarimelam.

#ScindiaKanyaVidyalaya #BestGirlsBoardingSchool #Dharohar

The Shrimant Madhavrao Scindia Dharohar Fest 2022 has begun with over 150 students from eight premiere schools going through the Registration.

We welcome

Rajmata Krishna Kumari Girls’ Public School (Jodhpur),

École Globale International Girls School (Dehradun),

Sunbeam Lahartara (Varanasi), Stepping Stones School (Aurangabad),

Sunbeam Varuna (Varanasi),

The Hyderabad Public School (Begumpet, Hyderabad),

Vidya Devi Jindal School (Hisar),

The Rajkumar College (Rajkot) and the HD Foundation School,

Haldwani as the observer school.

#ScindiaKanyaVidyalaya #BestGirlsBoardingSchool #Dharohar

At SKV, we are deeply involved in Heritage preservation and propagation. Every year we host our Dharohar festival in which we pick up a theme from a period of Indian History or the heritage of an Indian State. We then research the heritage in performing & visual arts, culinary arts & built heritage. We invite girls schools from all across the country to participate in competitions planned around these themes. A prize of Rs 1 lac is won by the top performing school. The money is meant to be spent on advancing the cause of Heritage studies back in their school.

Over the years, the following culture and art forms have been resurrected and propagated through our Dharohar Festivals:

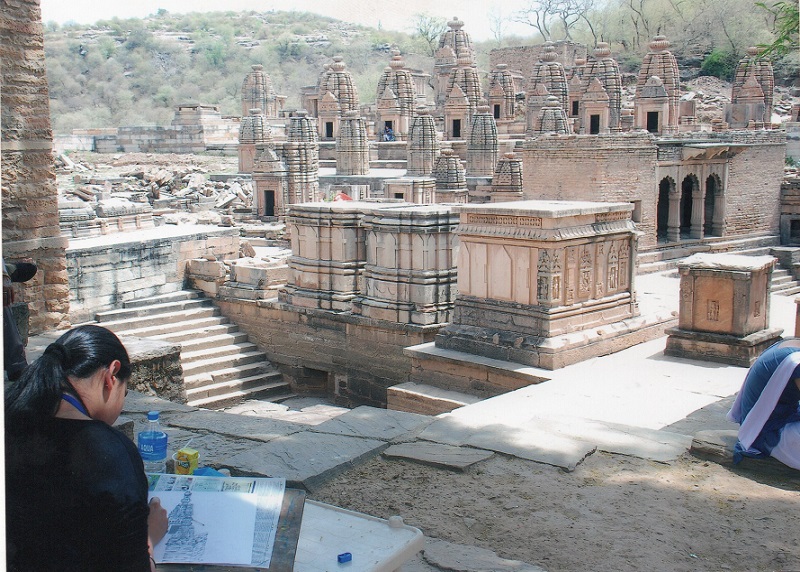

Mughal Heritage: Dastan goi, sher-o-shayari, dastarkhwan, quavvali, Period dress creation, workshop on Pointing at rebuilding excavation sites.

Maratha Heritage: Art of tying a Maratha Pagri and Maratha Kashta Sari, Designing bridal jewellery, Hari Katha, Maratha Thali, Batto bai dolls, Lavni

Kashmir Heritage: Band Puather, Rauf, Kashmiri cuisine, Kasida kaari, Khatam band talav.

Sikkim Heritage: Limbu Dance, Samlo folk songs mask making, prayer wheel creation, Jhyali painting, Tashi Tegye, cuisine from the Moktu

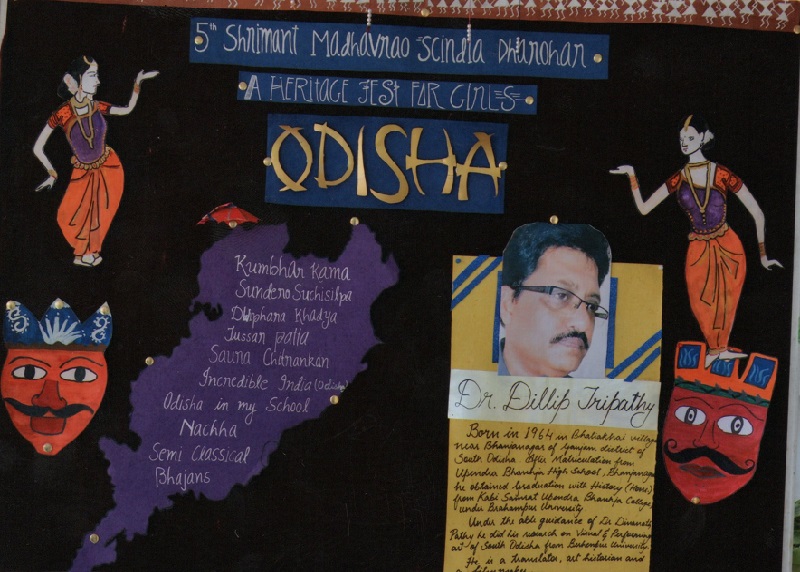

Odisha Heritage: Dwipahara Khadya, Kumbhar Kaama, Jaya dev's Geet Gobindo recital, Saura painting, Tussar pata painting, Sundero Suchishilpa, Nachcha folk dance

SANKALP

"One Undertaking, Many Outcomes"

- Improves women's hygiene

- boosts indigenous machines

- provides jobs in an entrepreneurial venture

- gender-sensitization

- community service

The girls at Scindia Kanya Vidyalaya, Gwalior, India, were looking for opportunities to provide meaningful community service in and around their city. Their research and surveys showed that a large population of Gwalior lives in slums, with no access to basic services like water and sanitation imposing a severe hardship, especially on the female population. Hygiene and cleanliness which is vital to women's health is poor and on the lowest priority. Awareness and availability of hygiene products like sanitary napkins is absent. Where the basic needs for life are not available, these women can't think of buying expensive sanitary napkins available in the markets. Thus these women resort to unhygienic alternatives ranging from rags, leaves and even sand !

The Principal Mrs. Nishi Misra and the students recognized this problem and applied themselves to finding a way to supply sanitary napkins to the underprivileged women of 2 villages. After intense brain storming and research,they identified a low cost sanitary napkin manufacturing unit. This fully indigenous machine was designed, created & tested by Mr.A.Muruganantham of Jayaashree Industries, Coimbatore. The machine had been awarded the National Award for Best Innovation by the then President of India,Mrs. Prathiba Patil. This machine uses bio degradable materials like banana fiber to make low cost sanitary napkins and can be run by students after minimal training.

Excited at theprospect of this hugely meaningful service, the students set about finding waysto finance this machine and the first consignment of raw material. Funds were raised from Funfairs, HouseSales, contributions from Alumni and from The Friends of Round Square, an international organisation of which the school is a member. The machine arrived and was installed amidst great curiosity and enthusiasm among the students and staff.The simple training for working the machines was imparted to a pioneering group of staff and students.

The simple machines are laid out on 8 stations -- each the size of a student's study desk. The process begins with tearing the raw-cotton sheets and mixing with binding cotton in a Mixer Jar. The material is weighed and 12 grams of material is portioned into moulds which are compressed under an air-powered stamp. After inserting a water-proof strip,this initial napkin is sealed into absorbent tissue-cloth. An adhesive is applied and covered with a strip of oil-paper which can be stripped off to set the napkin in place. A maternity version with longer 'tails' is also being manufactured. At the end of the assembly line, the napkin is sterilised in a UV chamber. Sets of 8 napkins are packed together with cling-film and are ready for distribution.

The studentstarget to distribute the napkins to 250 women in the villages of Zagra, Sausa and on the outskirts of Gwalior with a sustained and unbroken supply. Batches of students spend time with the womento educate them about the use and disposal of the napkins. The huge demand for the product has set the students to work out a small scale industry model to make it self-sustaining. The model holds the possibilityof being transferred to villages as an entrepreneurial venture too. There is a huge demand for the product since it costs just Re 1/- per napkin.

Since this willbe an ongoing program, the raw material will be purchased from funds collectedthrough charities conducted from time to time. The students contribute 'shram-daan' (service by labour) andearn 'volunteer hours'. Boys and girlsof many member-schools of Round Square in the country and abroad, have signed up for the 'shram-daan'which will go a long way in gendersensitization.

The initiativeof setting up this unit to produce and distribute sanitary napkins to underprivileged women, is named "SKV-Sankalp"- a resolution taken by SKV girls to help women to live with dignity.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)